GONON TECHNOLOGY

Professional solution for industral heating

About Gonnon

Gonnon Technology is an innovation enterprise dedicated to environmental protection technology and green energy. We integrate R&D, production, sales, and after-sales services all in one company. It is based on the provision of a clean heating solution to meet production needs of the customers, and at the same time, it delivers also good products. Careful services, reasonable price so that domestic and foreign customers are assured of a sense of satisfaction.

Today, Gonnon Technology will deeply cultivate China market, pay attention to the Asia Pacific, and eyes open to the world. We will continue to meet the international standards of design requirements and high-quality services, to provide customers with first class industrial heating equipment and comprehensive presales until after sale service.

In the future, Gonnon Technology would keep the mind of tolerance, the spirit of brave, the concept of seeking truth and perfection, and work with employees to achieve dreams, enhance value with customers, and win social respect with the industry!

Development History

12015 - Company Establishment

Guangdong Gonnon Intelligent Manufacturing Equipment CO., Ltd.(brand name Gonnon Technology) was formally established in 2015 on the banks of the Dongjiang River in Liuhua Street, Dongcheng District. The company focuses on the research and development, production, sales and engineering services of gas-fired thermal oil heaters(gas-fired mold temperature controllers), and is committed to providing customers with efficient, stable, high-quality, energy-saving temperature control equipment and providing a complete set of solutions.

22017 - Market Expansion and Technology Accumulation

With the continuous advancement of the company's technological research and development, products are constantly updated and iterated, and the application areas of products are gradually expanded, covering more than 120 industries such as composite materials, new energy, chemical pharmaceutical, furniture panels, die-casting, food production, and shoe materials. Through technological innovation and high-quality service, Gonnon Technology has gradually established a good market reputation.

32021 - High-tech Enterprise Certification

In 2021, it was awarded the "National High-tech Enterprise Certification", demonstrating Gonnon Technology's excellence in the field of energy-saving, environmentally friendly and temperature control.

42022 - International Market Layout and Brand Upgrading

On the basis of deepening its presence in the Chinese market, Gonnon Technology has begun to focus on the Aisa-Pacific region and gradually expand into the global market. The company actively promotes its internationalization strategy, exports its prodects to many countries, and has more than 5,000 project cases, further enhancing its brand awareness at home and abroad.

52023 - Intelligence and Service Optimization

In response to the development trend of global intelligent manufacturing,Gonnon Technology has introduced intelligent technology and developed a full set of internet of Things control systems to achieve intelligent and automated upgrades of temperature control equipment. At the same time, the company has developed an after-sales service system, and continuously improved the pre-sales, in-sales, and after-sales service system to provide customers with all-round, high-quality, cost-effective, full-set solutions and user experience, further enhancing market competitiveness.

62024 - Future Outlook

Looking to the future, Gonnon Technology will continue to uphold the broad mind of "embracing all rivers" and the spirit of "seeking truth and excellence", pursue dreams with employees, and enhance value with customers. The company will adhere to the design and service optimization in accordance with international standards, and strive to become a leader in the field of global industrial heating equipment, achieve win-win results with industry partners, promote sustainable development, and win respect for the society.

What We Provide

Innovative Solutions Backed by Expertise and Efficiency

Strong Abilities of R&D and Technical Team

Gonnon Technology always keeps innovation and practice, to draw on the valuable advice provided by customers. We will continue to develop new products with high effciency and energy saving performance. We ensure our customers can buy good quality and secure equipments.

Professional and First Class Service

We pursue the ecvellence, the endless progress, the development of our own potential, and stimulate own motivation; we never stop to achieve the perfection of own technology, to maximize our own value and that of our customers.

Ready to go, ensure the delivery within the schedule, the quality and quantity are exact as the specification of deal, to resolve your concerns.

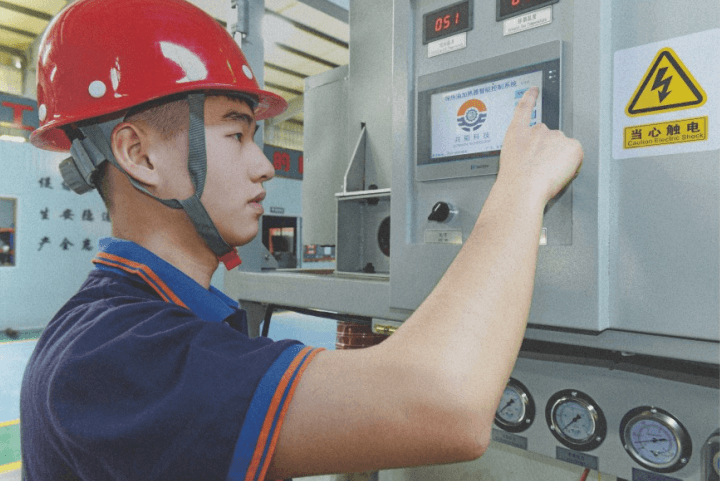

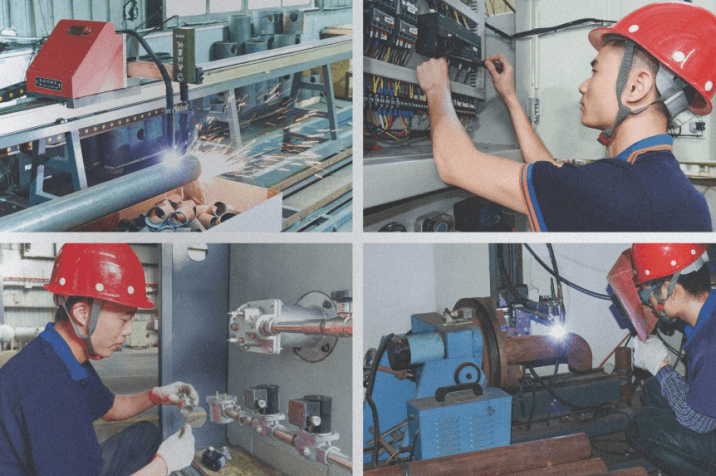

Standard Assembly Process

Each technician is fully trained to work in standardized assembly processes, it ensure that whole process would meet the professional requirements, to refine the division of labor and improve the precision and quality assembly.

Strong production capacity and perfect manufacturing system build our advantage of core competence. The large scale manufacturing system with rich products and complete types is a solid backing for the development of Gonnon Technology and expansion of our market.

Gonnon Technology (Internet of Things) Remote Monitoring Center Control System

It can be connected with computers and mobile phones, and users can remotely monitor the running status of the equipment in real time through mobile phones or computers, and can also operate the equipment remotely.

When the equipment fails and the user cannot handle it, the manufacturer can be contacted to provide maintenance or repairguidance in real time through remote monitoring.

Powerful and Professional After-sale Monitoring Platform of Gonnon, Quick Response to Customers!

- Scan code for repairs: Customers do not need to download the APP, and the WeChat scan code applet to apply forrepairs can generate a repair work order.

- Work order dispatch: The tasks are allocated in a timely manner, and at the same time, the dispatching situation is reported to the customer, which saves the waiting time for the customer.

- Check-in and punch-in: Grasp the dynamic location of personnel in real time, and make strategic plans for the task metal.

- After-sales process feedback: On-site maintenance mobile phone photos and videos, real-time feedback, full transparency on site, and real-time grasp of progress.

- Costomer comments: Accurate return visits, real comments and evaluation, and big data support performance appraisal.

- The standardized after-sales service process reduces unnecessary communication costs, improves the exection efficiency of maintenance personnel, and greatly improves customer satisfaction.

Gas Mode Thermal

Oil Heater

Seventh Generation

Machine Product

&

Six Generation

Machine Product

Product Features

(Seventh Generation Machine Product)

1Appearance Design

The appearance design adopts a new combination of silver and grey, which is majestic and ingenious. Beautiful and decent, highlighting the spirit of our company's technological innovation.

2The Internet of Things Operation System

Can be connected to computers and mobile phones. Users can remotely monitor and operate the operating status of the equipment through mobile phones or computers. This function can be monitored through circuit and gas monitoring functions without going to the equipment site. Sitting in the office to pass the mobile phone or computer can calculate the cost in real time, and when the equipment fails and the user cannot handle it, the manufacturer can be contacted to provide maintenance or repair guidance in real time through remote monitoring.

3Circuit Monitoring Function

Which can monitor the voltage and current in real time, and prompt alarm in time when abnormal.

4Gas Monitoring Function

Which can monitor the gas pressure in real time, the instantaneous maximum flow, the total gas usage, and alarm when abnormal.

5Gas Leakage Alarm Device

Can monitor the concentration of combustible gas in the cabinet in real time. When gas leakage occurs, it will automatically alarm, prompt and close the main gas source valve to reduce potential safety hazards and maintain the safety of customer's lives and property.

6Exhaust CO Emission Monitoring Equipment

Real-time monitoring equipment exhaust emission of various harmful gases, when the content exceeds the national standard safety value, it will automatically alarm and stop the equipment heating work, which greatly provides a healthier and more comfortable working environment for front-line workers.

7Using the Stepless Automatic Conversion Function of Large and Small Power

It can automatically adjust the combustion power according to the actual heat required by the heating equipment accurately control the temperature, aviod the waste of gas caused by excessive heat output, and achieve more efficient energy utilization to save energy. The role of emission reduction.

8Gas Pressure Stabilizer Valve

When the inlet pressure fluctuates, the pressure stabilizer device in the valve will act accordingly to adjust the opening degree, which can keep the outlet pressure stable and make the equipment have super field adaptability and reliability.

9The Ultraviolet Fame Detector

Used for fame detection. It adopts a new type of ultraviolet photosensitive element, which can monitor the fame temperature in real time. It has the advantages of high sensitivity operation, reliable performance and long life.

Product Features

(Sixth Generation Machine Product)

1Compact design and small area occupied, easy installation.

2SIEMENS PLC control module, smart interface for easy operation.

3Automatic controlling and monitoring system, safety and reliable.

4One button start and smart shutdown, no special watching.

5Oil tank on top and working temperature no more than 50℃, completely avoiding the oxidation of thermal oil.

6Air preheater and two section burner, low exhaust air temperature and low heat loss, high thermal efficiency.

7Equipped with integrated explosion-proof door as protection of explosion.

8Low nitrogen, the exhaust emissions meet the requirement of national environmental protection rules.

Our References

Wood Plate Industry (Single Layer Press)

Wood Plate Industry (Multi Layer Press)

Wood Plate Industry (cold in and cold out high-gloss sheet)

Shoe Industry

Paper-plastic Tableware Industry

Leather Industry

Textile Dyeing Industry

Wood Carbonization/Drying

Press Machine for Molding Door/Molding Line

Reactor & Chemistry

Coating Machine

PVC Fitting Industry

Latex Foaming Industry

Food Industry

Circuit Board Fitting Industry

Non-woven Industry

EVA Foaming

Kneading Machine

Printing Industry

Subscribe to our newsletter

Sign up with your email address to receive news and updates